Aerospace

What is the aerospace industry? It is the manufacturing of commercial or military aircrafts such as airships, missiles, satellites, aircraft engines and more! According to Britannica, over half the industry is made of American companies. Some of these include companies include familiar ones you may have heard before such as Boeing, GE Aviation, Honeywell and Lockheed Martin. Aerospace companies are not only responsible for the manufacturing process, but also work in research, development and testing of aircraft both old and new. This is a particularly innovative industry is vital to ensure national security safety (military aircraft) and basic air travel.

Though the industry is constantly growing, developing and changing with new technologies always on the horizon, dust collection and industrial air filtration plays a role in the manufacturing process.

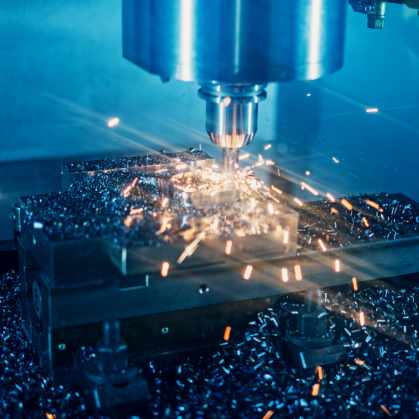

Welding, Plasma Cutting, Metal Grinding

Many manufacturing processes are involved in aerospace applications including welding, plasma cutting, metal grinding, and other forms of metal manufacturing. Downdraft tables and welding stations are used which is where harmful dust and fumes can be generated. Toxic weld fumes and metallic dust particles can cause health problems to workers in the plants and an overall unsafe working environment.

Dust Types

- Weld Fumes

- Metallic Particles

- Sanding

- Thermal Spraying

- Chemical Dusts

- Carbon Dusts

Adhering to Standards

Many people rely on the aerospace industry, so it is important that the products created meet safety guidelines and are of the highest quality. Safety is the main key to opening the door to allowing planes and other aircraft to be able to fly high in the sky! Dust control plays a part in that safety process. A safe and healthy workplace is created with proper industrial air filtration. This also allows for better employee retention in creating a safe product.

OSHA and PEL

Every manufacturing workplace has set rules in place that are set by the Occupational Health and Safety Administration (OSHA). This includes air quality levels. They have permissible exposure limits (PEL) on various dust types and substances. It is highly recommended that aerospace industries make sure they are following guidelines and regulations to not only prevent fines, possible plant closures but to protect their workforce.

Combustible Dust Risks

A lot of dust generated in aerospace manufacturing is combustible. This means that it is extremely likely to combust when ignited by an ignition source. Ignition sources can be a spark generated from equipment, electrostatic discharges, or even something as simple as a cigarette butt. That is why it is so important that work areas are kept clean and dust-free.

It is more than essential to protect workers and the manufacturing plant from dust explosions. Once it ignites there is no stopping the explosive chain reaction. Implementing dust control and industrial air solutions is a good preventative measure.